Production tool

Thanks to its know-how and its equipment, LBI is at your service to offer you a wide range of parts made to measure according to your needs. The various manufacturing steps are meticulously monitored by an experienced and highly qualified team.

Custom

production

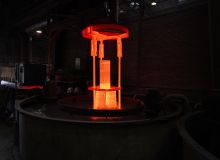

Everything starts with the development of the alloy you have selected, standard alloy or developed specifically for you.

Casting by centrifugation, horizontal and vertical, allows the production of perfectly uniform and more resistant parts. Casting by centrifugation is casting under centrifugal pressure which causes very significant degassing within the alloy which rejects all the impurities that a bath of liquid metal may contain into the bore.

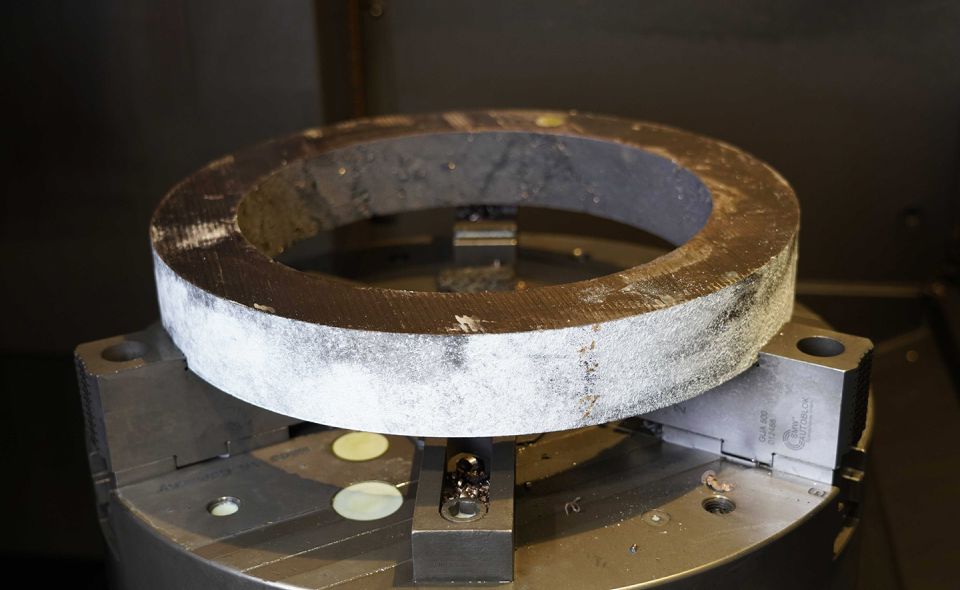

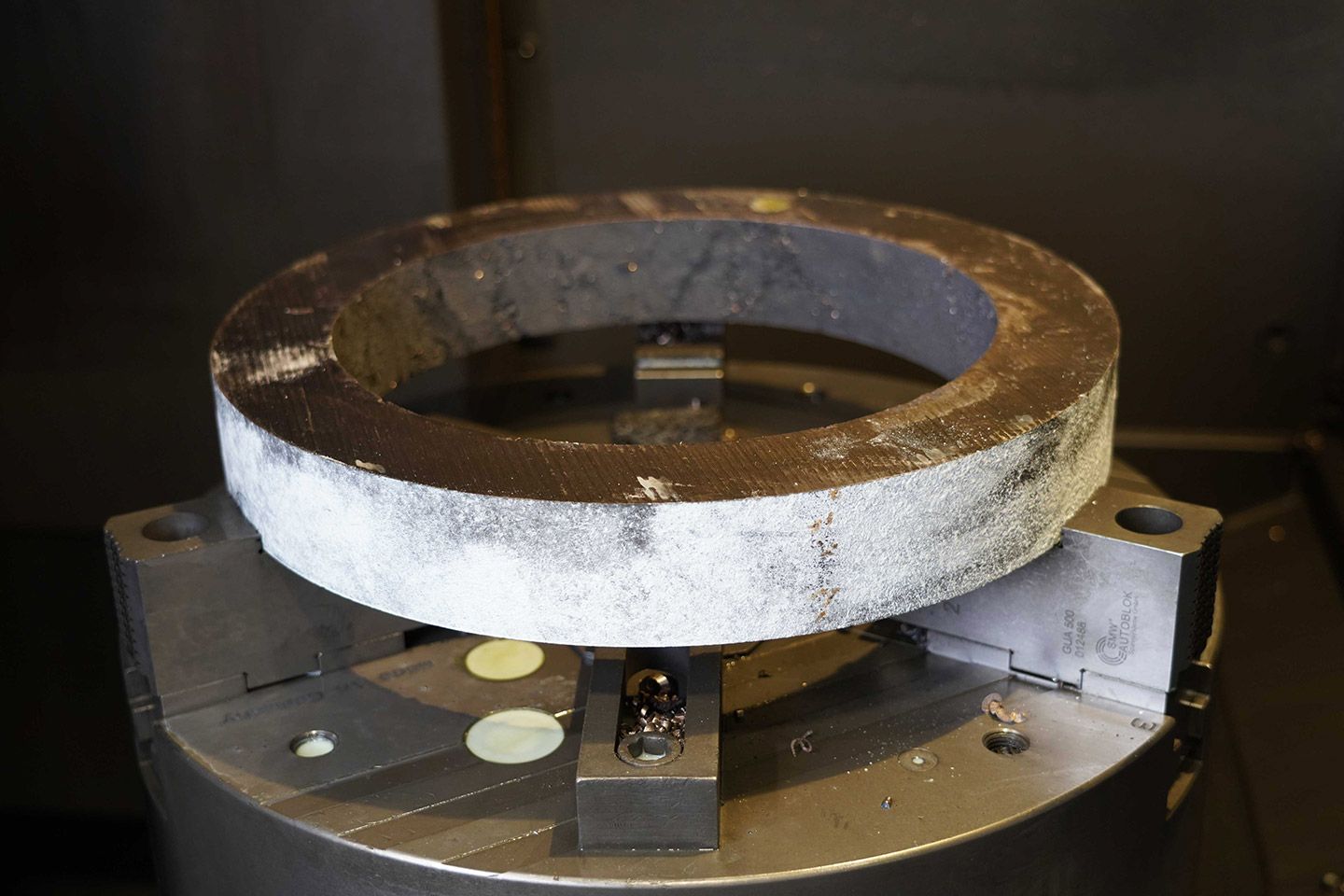

Centrifugal casting then gives the shape that you have defined for us: tubes, rings, crowns, rings, sockets, flanged cobs.

This manufacturing process, LBI applies it to small parts as well as certain parts with larger diameters. Indeed, LBI offers its customers parts with non-standard dimensions, reaching 6,000 mm in diameter and up to 20 t.

Likewise, production is dedicated to unique pieces as well as small series (from 5 to 10 pieces up to approximately 200 pieces). Whether it is unique pieces or small series by delivery, we will have manufacturing resources adapted to your request.

After a heat treatment carriedout if necessary, your part will join our machining workshop dedicated to machining operations allowing to deliver parts to the dimensions you want, whether they are blanks or fully machined parts ready to be integrated.

The implementation of a continuous and reasoned investment policy allows the regular renewal of its equipment, so as to offer cast parts at the best cost and in the best conditions.

Foundry

Melting

-

12 induction furnaces: 2 x 300 kg, 2 x 600 kg, 2 x 1200 kg, 2 x 1500 kg, 2 x 2400 kg, 1 x 7000 kg, 1 x 13000 kg

-

9 gas ovens from 600 kg to 900 kg

Centrifuge

-

Short horizontal: 4 machines, Ø 80 to 1,000 mm, length 200 to 1,000 mm, up to 1 ton

-

Long horizontal: 2 machines, Ø 3,200 to 1,000 mm, length 2,000 to 4,000 mm, up to 6 tons

-

Vertical: 6 machines, Ø 300 to 6,000 mm, length 200 to 3,000 mm, up to 20 tons

Heat treatment

Furnaces

-

2 ovens Ø 1,000 x 3,000 mm, temperature 1,150° maximum

-

1 oven Ø 1,000 x 2,500 mm, temperature 1,250° maximum

-

1 oven Ø 1,800 x 2,250 mm, temperature 1,150° maximum

-

Water, oil or air hardening, Ø 2,000x, length 3,000 mm maximum

-

Other income: stress relief, softening

Rough machining

-

Parallel lathes up to Ø 1,100 mm, length 6,000 mm

-

Vertical lathes up to Ø 5,600 mm, length 4,000 mm

Finish machining

Parallel lathes

-

Up to Ø 500 mm, length 1,000 mm

-

Up to Ø 1,200 mm, length 8,000 mm

-

Up to Ø 1,060 mm, length 10,000 mm

Vertical lathes

-

Up to Ø 1,250 mm, length 600 mm

-

Up to Ø 2,200 mm, length 1,750 mm

-

Up to Ø 4,100 mm, length 2,000 mm

Milling

-

Length up to 3,400 mm, depth up to 1,500 mm, height up to 900 mm, maximum weight of 12 tons

Welding

-

MIG, MAG and TIG

Others

-

Drilling, fitting, grinding and reaming