Company

For more than 100 years, LBI has been producing metal parts, in bronze, stainless steel, aluminium and special alloys, obtained by the centrifugal casting process.

History

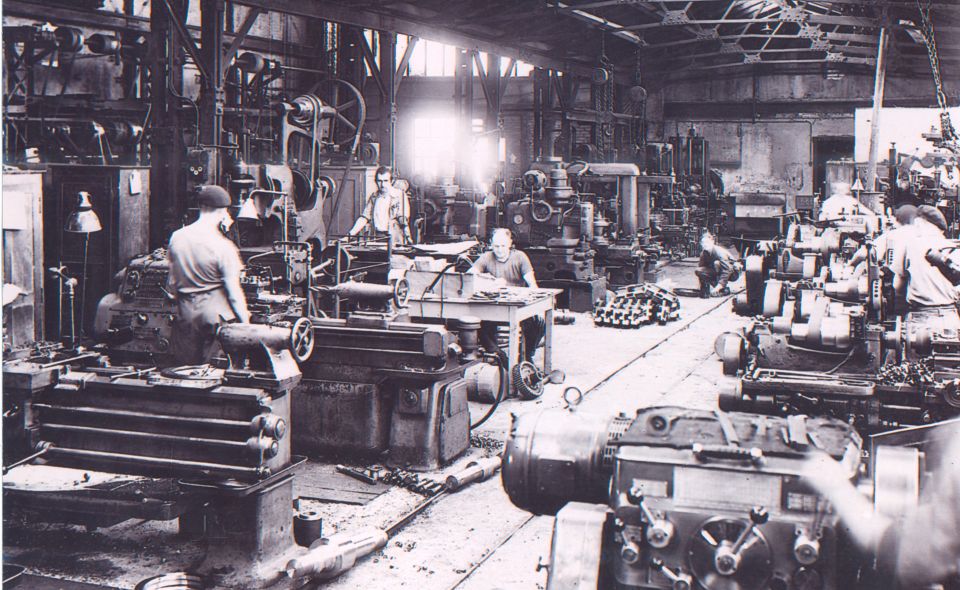

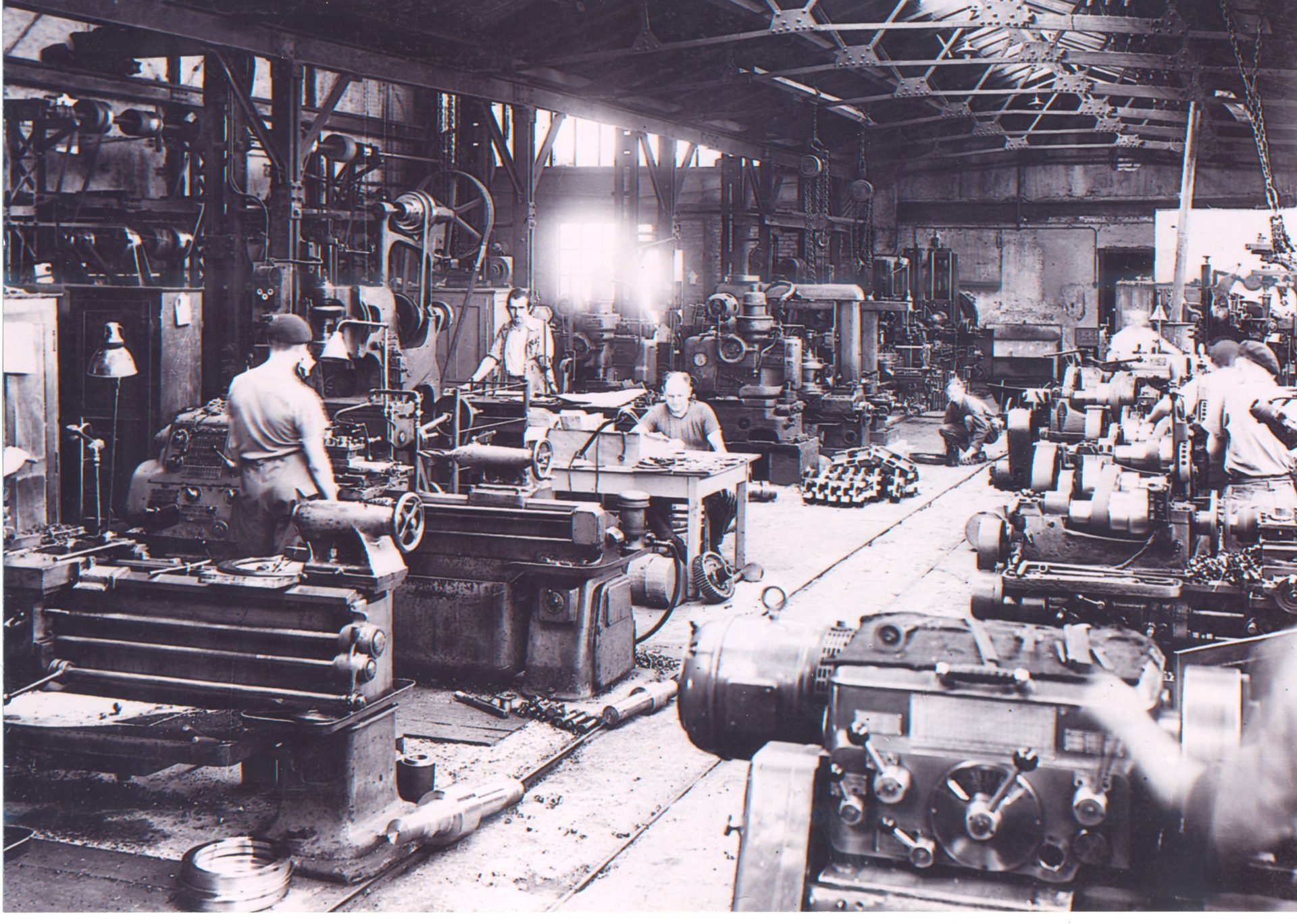

Formed in 1919, Les Bronzes d’Industrie (LBI) were initially specialists in heavy mechanical manufacturing operations, including the production of worm wheels.

They soon became dedicated to foundry activity and specialized in bronze and aluminium sand castings. In 1960, LBI made their first major advance with a then revolutionary technique: the centrifugal casting process (or spun casting).

Based on the exceptional results of this new process, LBI decided in 1971 to put an end to their traditional foundry and to dedicate themselves exclusively to the centrifugal casting (or spun casting) of non-ferrous alloys. LBI developed and elaborated their own alloys and soon became one of the French specialists regarding wear resistance parts.

In 1976, the company entered the export markets, thanks to its development of stainless steels. LBI design and produce their own machines, and have dimensional capacities unique in the world.

Today, LBI have a worldwide presence and export more than 80% of their production.

International dimension

LBI est une entreprise qui a su très tôt conquérir les marchés internationaux de part sa technicité et la tenue de ses engagements qualité qui lui ont permis d’obtenir la reconnaissance de ses clients français puis étrangers.

Dès les années 70, LBI a compris l’importance de l’export dans sa stratégie commerciale. De nombreux clients issus de secteurs d’activité différents nous ont fait confiance et notre part export ne cesse dès lors de croître, atteignant en 2020 près de 80% des ventes à travers 35 pays.

Aujourd’hui, LBI bénéficie d’un réseau commercial étoffé par :

- un service commercial multilingue à votre écoute ;

- un réseau d’agents commerciaux, de représentants et de distributeurs dans le monde entier ;

- la création de deux bureaux commerciaux, l’un en Allemagne (LBI Guss) et l’autre en Angleterre (LBI Castings).

85%

35

2

Innovation

LBI is at the heart of innovation. It’s Research & Development laboratory allows it to carry out studies aimed at improving it’s foundry processes and the technical characteristics of cast parts as well as the creation of innovative alloys that can respond to multiple technical problems.

These tailor-made alloys are made according to the projects of its customers or resulting from internal research such as EXIUM®AM with remarkable damping properties and very good resistance to corrosion as well as ALUSiC® with rigidity and conductivity high heat.

Thanks to it’s innovation policy, LBI has integrated into many cutting-edge sectors of activity such as the aerospace field, in particular with the InSight mission landed on the planet Mars in November 2018, which embeds components made of EXIUM® alloys. AM and ALUSiC® developed by LBI.

LBI settles in space but also in the marine environment. Indeed, LBI is developing in the defence market with parts intended for military ships such as nuclear submarines and aircraft carriers.

Commitments & Quality

LBI understood very early on that in order to be able to meet the requirements of advanced industrial sectors, it was essential to enter into the quality approach.

Also, from 1980 the company invested heavily in creating its own Quality Manual. This document, which is regularly updated, complies with the latest quality organization standards. LBI is ISO 9001:2015 certified.

The desire to innovate is further expressed by the human policy exercised within the company: the very strong team spirit and the high qualification of the staff make it possible to respond effectively to the requirements of the market, both nationally and internationally. In a constant concern for training, LBI has had an integrated learning center since 1928.

An environmental approach was initiated in 2007 to limit energy and resource waste and thus adopt a more sustainable mode of operation. It has also been ISO 14001:2015 qualified since 2016.

Investment

To face the evolution of increasingly competitive markets, LBI has adopted a strategy of regular and reasoned investments during its history allowing it both to modernise it’s production tools and to gradually adapt its production capacities to the market.

Over the past decade, two waves of investment have been notable:

-

The first from 2013 to 2016, LBI invested nearly €7.5 million with the construction of a new machining hall and the purchase of several machines including a 3-axis vertical lathe with a capacity of 4 meters in diameter

-

The second from 2020 to 2023 where LBI continues its renewal and modernization process with investments estimated at €6.5 million: purchase of new land opposite the company to double its operating surface, construction of a new shipping and storage hall and reorganization of the company in order to improve productivity and working conditions.